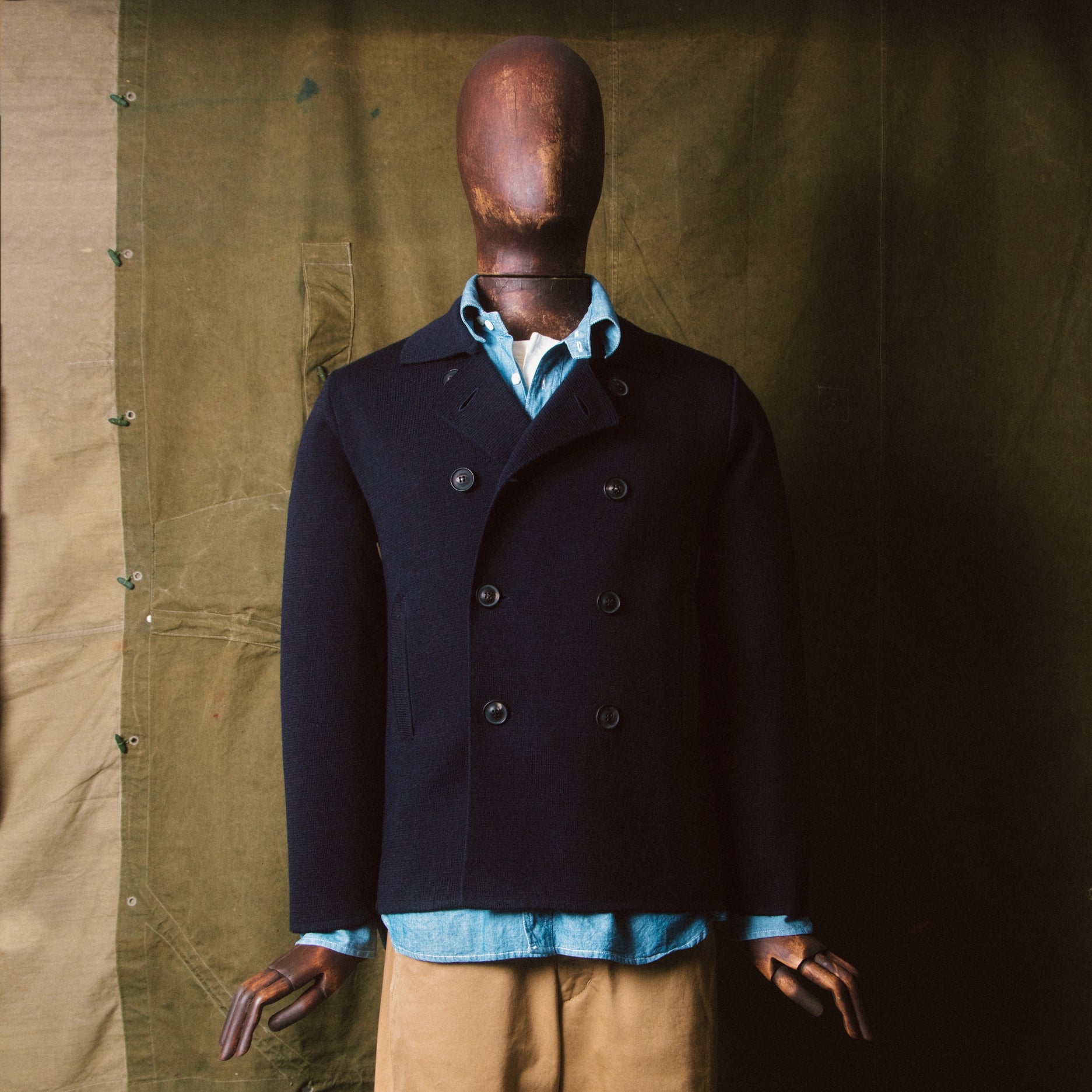

The world of fashion and design is full of textures and materials, but there is one that stands out for its timeless elegance and incomparable softness: suede. This refined material offers a unique sensory experience while adding a touch of luxury to everything it touches. In this article, let's delve into the world of suede leather, exploring its distinctive features, its manufacturing process and why it has become the go-to choice for those seeking quality and style.

What is Suede Leather?

Suede leather, also known as suede, is obtained from the inner side of the hide. Its soft, silky texture is the result of a careful sanding process that creates a short-fiber surface, giving the leather a velvety appearance. Unlike smooth leather, suede leather offers a softer feel and a subtle finish that evokes sophistication.

How to get Velvet Leather?

Suede leather is obtained from the inner side of the skin, generally from calf, goat or deer. The process of obtaining suede leather involves several carefully orchestrated steps to ensure the soft, velvety texture characteristic of this material.

1. Selection of Skins: It all starts with the careful selection of skins. Calf, goat or deer skins are preferred because of their fineness and flexibility.

2. Soaking: The skins are first soaked in large vats of water to hydrate them. This process softens the skin, making subsequent work easier.

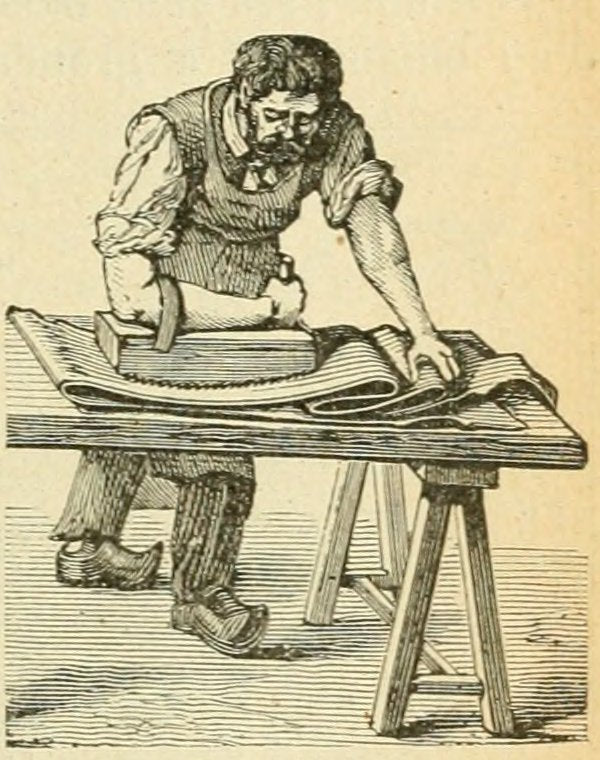

3. Fleshing: After the skins are soaked, fleshing is done to remove the hair and the outer layer of skin. This exposes the inner side, also known as "the flower."

4. Tanning: The fleshed hides are then treated in a tanning solution to preserve them and make them rot-proof. There are several tanning methods, but chrome tanning is often used for suede leather because of its speed and efficiency.

5. Dyeing: After tanning, the hides are dyed to the required color specifications. Suede leather offers excellent dye absorption, allowing for a wide variety of colors and shades.

6. Drying: The dyed hides are then dried in a controlled process. It is essential to dry the leather evenly to avoid any warping or deformation.

7. Sanding: The distinctive feature of suede leather is the sanding process. The interior side of the leather is carefully sanded to create a short fiber surface, giving the leather its velvety appearance. This process creates a soft, luxurious texture that is pleasant to the touch.

8. Finishing: Finally, suede leather goes through a finishing process to seal in the dye, improve water resistance, and preserve its velvety texture.

Quality and Durability:

One of the most attractive aspects of suede leather is its exceptional durability. Although its touch is delicate, suede leather is robust and resistant to daily wear and tear. It is also less likely to show signs of wear such as scratches, making it an ideal choice for high-quality pieces intended to last over time. Opting for suede leather items means investing in durability and quality.

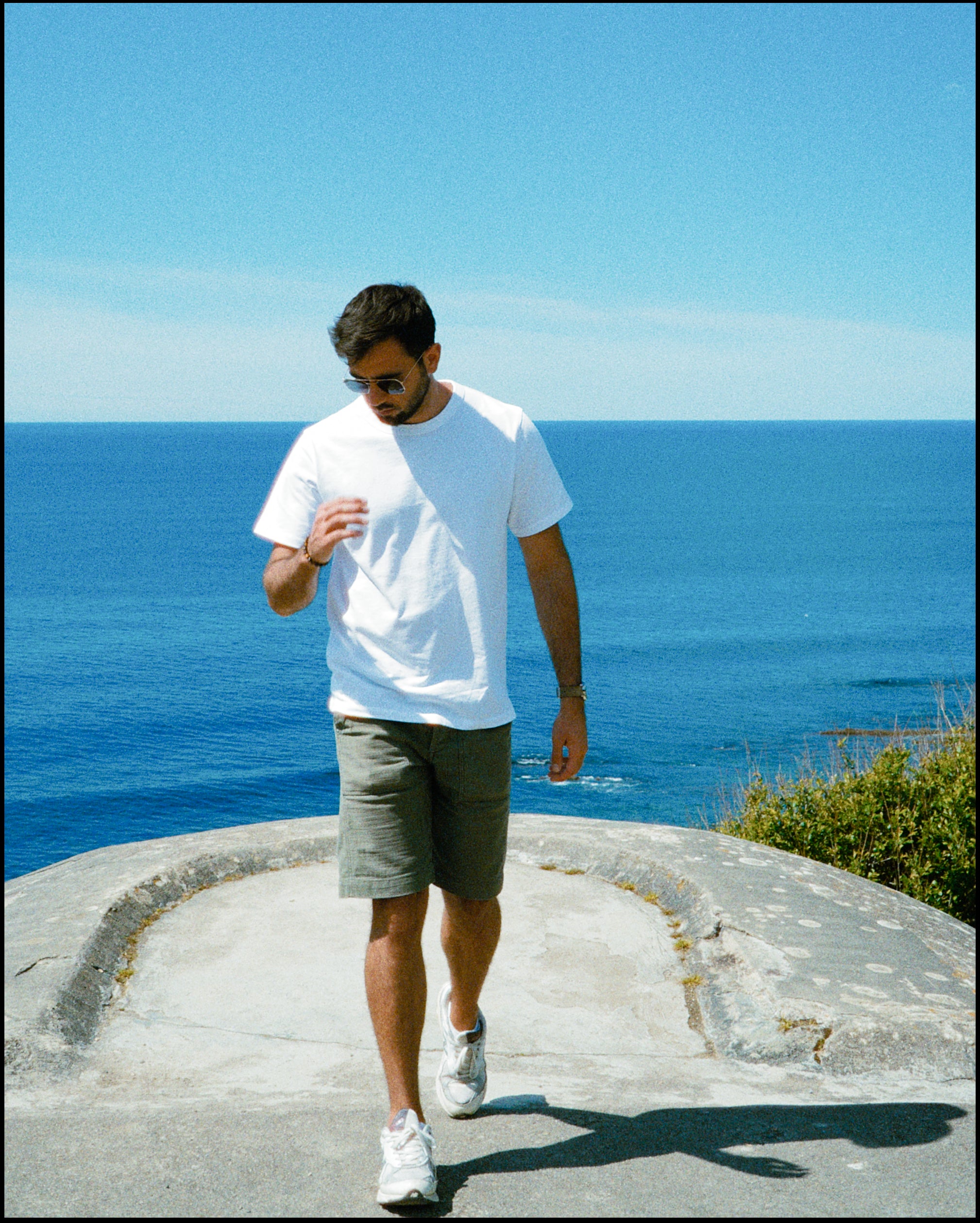

the Interview? My practical advice:

If you are concerned about maintenance, suede leather does not disappoint. It generally only requires regular brushing with a soft brush to preserve its original appearance. If there is a stain, gentle cleaning with a damp brush can often solve the problem. However, it is always recommended to carefully follow the manufacturer 's specific care instructions to ensure a long life for your suede items. In my case, for example, I take this approach to the interview.

Signed David. Grojean